Industry 4.0 is allowing us to move towards a more efficient, sustainable and profitable supply chain. But this fourth industrial revolution does not come alone. Digitisation and the world of mobile apps are responsible for keeping the entire system interconnected.

Although industrial digitisation 4.0 is the basis, mobile applications are having a huge impact when it comes to driving the development of this industry and today, we will tell you how they do it.

Index:

- What is industry 4.0 and why is it important?

- Mobile apps in the digitisation in industry 4.0

- Why is the digitisation in industry 4.0 driven by apps?

- Yeeply supports companies in their digitisation towards Industry 4.0

What is Industry 4.0 and why is it important?

This 4.0 industrial digitisation, or also called the fourth industrial revolution, is due to two factors. On the one hand, to the implementation of digital transformation. On the other, to the incorporation of advanced technologies such as Big Data, implementation of predictive AI systems, Internet of Things (IoT), robotics or cloud computing.

Its revolution lies in the fact that it unifies and centralises all manufacturing processes, and as a result achieves more efficient and profitable production chains.

All the technological elements that are used in this industrial revolution contribute to achieving production objectives and achieving intelligent manufacturing practices that allow interaction with workers. This system makes it easier to customise products, improve their price and be more innovative, allowing organisations to be much more competitive.

Related article | The new trends and challenges of Agriculture 4.0

Mobile apps in the digitisation of industry 4.0

Within this fourth industrial revolution, mobile applications are helping to boost the productivity and performance of factories.

Despite using AI, IoT, etc., digitisation in industry 4.0 is powered by mobile devices. Without this technology, it would be impossible to carry out his innovation process.

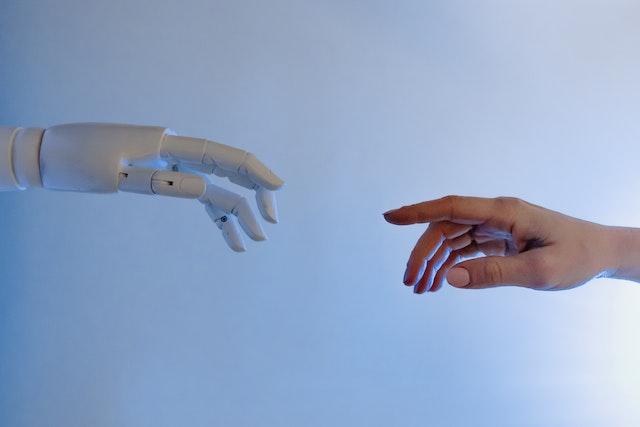

Mobile devices function as a link between workers and technology. Mobile apps allow you to easily connect and communicate with AI or IoT, creating an agile, productive and truly collaborative environment between person and machine, where each link works correctly and drives the rest.

The key to competitiveness and innovation in Industry 4.0 lies in mobile applications, which combine the ability to extract data from the IoT, with the ability to connect different devices that allow AI to analyse the information. As a result, quality information is available, that allows generating new and better market strategies.

Among the extra advantages that mobile Apps provide, we find the elimination of paper, better management and assignment of tasks to different employees, the promotion of collaboration and teamwork and, as if that were not enough, they are easy-to-use applications, cost-effective and available for almost any device with internet access.

In conclusion, 4.0 industrial digitisation without mobile applications would be a decentralised intelligence.

Why is the digitisation in industry 4.0 driven by apps?

These are some of the tasks that mobile applications allow to manage with a view to the digitisation of industry 4.0.

1. Elimination of paper

In the industry it is essential to register everything. Until now, companies have wasted a lot of paper in creating reports and notes. But now, thanks to mobile applications, this has changed.

Thanks to industry 4.0 apps, the same reports are generated in a virtual version, in a simpler way.

Another advantage is that this information is updated by simply entering the new data, which is stored in the company’s systems. Thus everyone can consult it at any time and without the extra cost of paper.

Recommended article | Interview with Héctor Badal (Yeeply) – How to take advantage of Digital Transformation in the post-Covid-19

2. Tracking of employees

A factory means a large number of people working and producing together. Tracking each worker is complex.

Until now, workers used RFID cards, but this system provides restricted monitoring, since it only works if the employee himself passes his card through the reader.

Thanks to mobile phones, this monitoring is more reliable. Phones that use BLE iBeacon or Wi-Fi software can help us track the location and activity of operators throughout the day to find out how many hours they work and what activities they carry out.

The application will also automatically notify the company of which employees have not come to their position.

3. Measurement of costs based on activity

Thanks to the use of mobile apps it is possible to measure and evaluate different activities and processes within a factory. The objective is to analyse the data obtained to determine key factors for production, such as the number of employees and resources required for each step within the manufacturing process.

To facilitate these calculations, employees use a mobile application to indicate what they are working on. At any given time. The application records when they started and when they finished, as well as the effort used through sensors capable of measuring movement and speed.

A cost report is generated, especially in factories with a large number of employees, and where it is difficult to carry out this type of measurement in a more traditional way.

4. Asset management

Through specific mobile applications equipment inspections, data on the operation can be collected in order to assess repair needs for each type of machinery.

Employees can quickly and easily request spare parts directly through these types of applications.

Through the data requested by the app it is possible to record the entire process (name of the employee, name of the part, details of the problem, date…). This information is stored in the application’s database so that it can be consulted in the future if necessary.

5. Work order management

Having a work team allows you to cover more functions and be more productive, but managing their tasks is complex.

Assigning objectives and functions to each worker, through email or reports on a daily basis, consumes a lot of resources and is not the most efficient.

Thanks to mobile applications for the digitisation in industry 4.0, this task is much easier. Managers, through this type of applications can manage tasks and leave specific guidelines to the workers who carry out the work.

Any changes or updates will also appear on the operator’s phone as a notification, speeding up communication and making work management easier.

You might be interested | The Best Apps for Entrepreneurs

Yeeply supports companies in their digitisation towards Industry 4.0

Yeeply provides key services for Industry 4.0 thanks to tailored mobile application solutions.

We bring together all the capabilities of Industry 4.0 throughout your ecosystem through an app.

Accelerate your digital transformation in Industry 4.0 and increase your productivity, income and profitability.

Contact our experts, they will be happy to help you!